Automatic Pouch Filling and Sealing Machine

Automatic Pouch Filling and Sealing Machine

What’s flexible pouch package?

Flexible pouch package is single-use bag commonly made of metal foil, plastic, and occasionally, paper. It’s used for packaging everything from snack foods to industrial liquids and are commonly found on supermarket shelves across the globe.

Flexible pouch package has become extremely popular over the past few years for food. This is beacuse many of them are resealable, environmentally friendly, and cheaper than alternatives like glass, metal, and cardboard containers.

They are used for packaging everything from granola to energy drinks. Their widespread adoption is linked to the fact that they have a much lower carbon footprint than the alternative packaging materials mentioned above and take up much less space in our landfills.

Pros of automatic pouch filling and sealing machinery

1. High-speed output -9,600 pouches per hour at the fastest.

2. Full servo drive, greatly reduce the demand for the operators, only one operator is needed.

3. Consistency of packaging

4. Reduced losses and savings in transport and storage costs

5. Reduced labour costs and carbon footprint

6. Stand-alone and end-to-end systems that make your production faster, smarter and more cost effective

Two Types of Flexible Pouch Package Machine

- - Flexible Premade Bag Packaging Machine

- - Flexible Form-Fill-Seal Packaging Machine

-

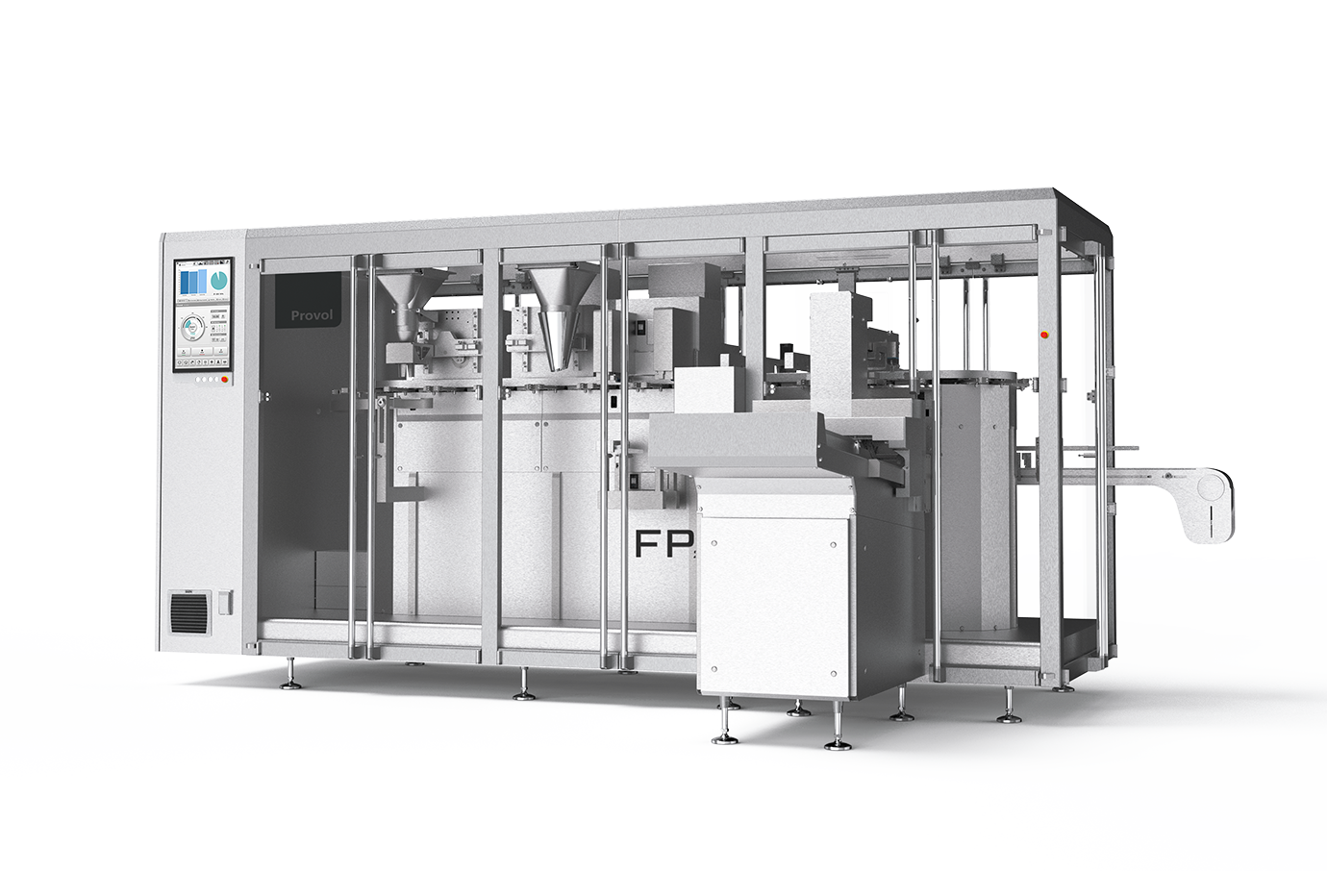

Flexible Premade Bag Packaging Machine

- Larger format range - from min bag width as 165mm to max bag width as 430mm, and the max bag height can be up to 1 meter.

- Online nitrogen flush to keep the product freshness and flexible vitality, which is suitable for different SKU quick changeover.

Applications

Features

- Quick changeover, less downtime.

- - Get production data at a glance

- - Stable operation for a long time

- - Food grade hygiene standards

- - Multiple inspections ensure product quality

- - Flexible space due to functional integration

How does it work?

This equipment fills premade pouches with product and seals them. Some pouch packing machines perform their operations in a rotary fashion and others in a straight line.

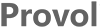

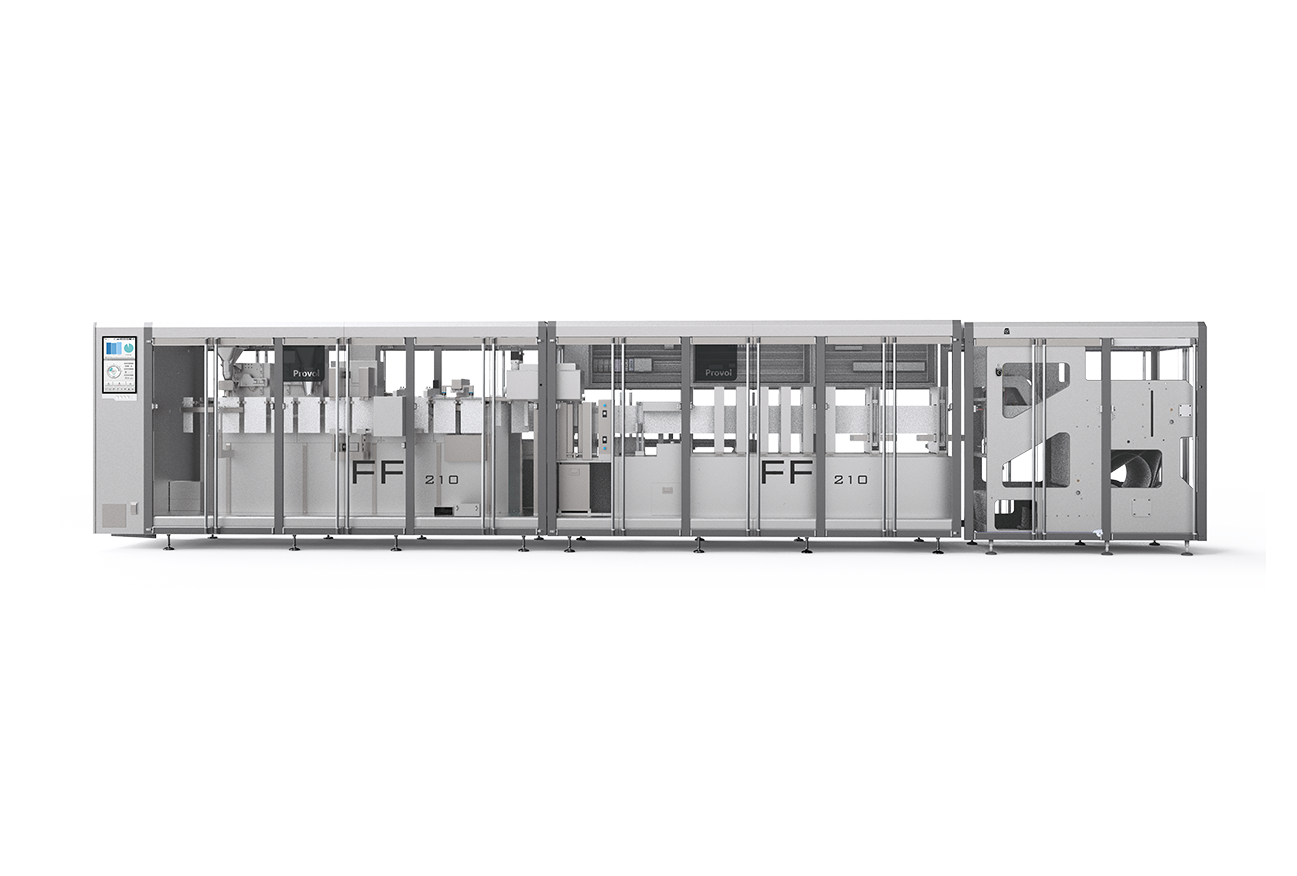

Flexible Form-Fill-Seal Packaging Machine

Packaging automation is the process of packing a product without human intervention. Over the years, automated packaging systems have moved from single machines that automate one step in the packaging process to machines that now seamlessly integrate all steps into the entire packaging process.

Applications

Features

- Easy to operate, friendly interface

- Stable operation for a long time

- Free changeover for multiple SKU

- Less film loss

- Flexible space performance

- Strict control of product quality

- Food grade hygiene standards

How does it work?

Roll stock refers to laminated film that's put onto a roll. It is often used with form-fill-seal machinery (FFS). These machines can be used to shape the roll stock and to create sealed bags.

Related Product

For more information about poutch packaging and other applications, welcome to contact us, please visit our website at http://www.provol.com/en/ We will be happy to help you out!